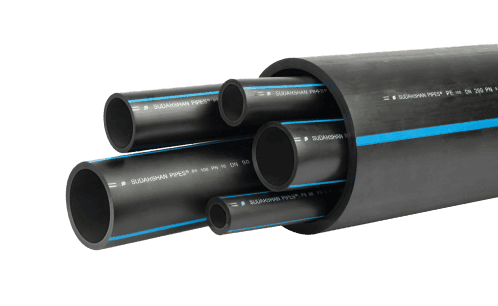

Sudarshan HDPE pipes adhere to two BIS standards: IS:4984 (2016) for drinking water pipelines and IS:14333 (1996) for drainage water lines. Currently we manufacture pipes from 20 mm to 400 mm diameter as per both standards in PE80/PE100. Our current install capacity is 30,000 MTP, with 14 extruders, the highest in South India. As per our expansion plan, a new imported plant of higher diameter HDPE pipes from 400 mm to 800 mm will expand our installation capacity to 48,000 MTP.

With highly technical manpower, in-house laboratories, testing and research facilities, 100% use of pre-compounded black material ‘Borrouge‘, online and offline stringent quality control system, Sudarshan HDPE Pipes are the No 1 quality you can trust.

Sudarshan HDPE pipes and specials are approved by several government authorities, such as the Rural Drinking Water Supply and Drainage Board, KUIDFC, KUWSDB, BWSSB, Minor Irrigation, TWAD, MP Jal Nigam, Kerala Water Authority, Maharashtra Jal Pradhikaran, TPHMED, and APHMED.

Benefits of HDPE Pipes:

- Design life of 50 Years

- Low Installation Cost

- Low Maintenance Cost

- Highly Sustainable – easy maintenance without interrupting the Water Supply, easily make Jointing / New Connection, and New Taping System

without interruption. - Compatibility – HDPE pipe fittings, including electrofusion fittings made from PE 100 compound, offer excellent compatibility with no leakage at joints. All types of moulded fittings are available in various sizes.

- Chemical resistance

- Flexibility

- Corrosion resistance

- Durable

- Light weight

- Low cost

- Abrasion resistance

- Joining with Butt

- welding

- Sustainability

- No leakage

- Eco friendly

- No effect of temperature up to 80C

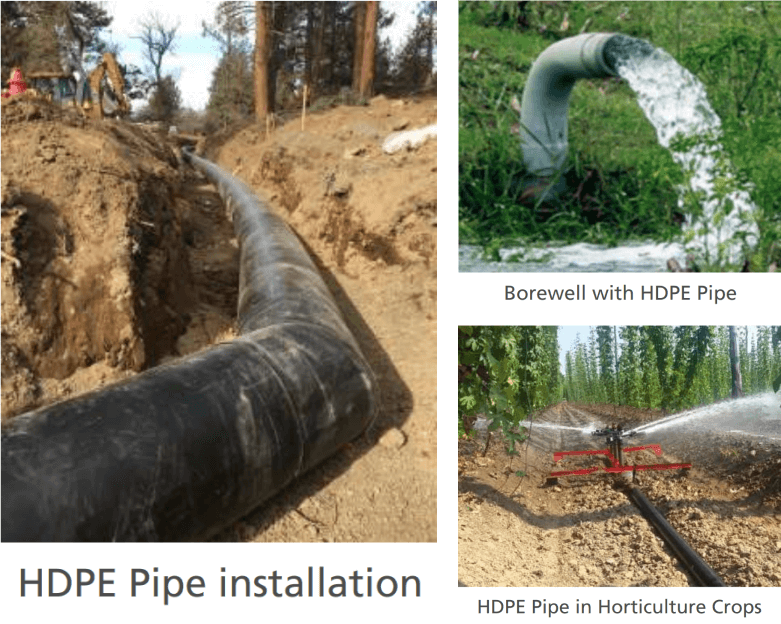

Due to its better properties than all conventional pipes-G.I./Seamless pipes/reinforced concrete pipes/Asbestos pipes. The central government and the state government have approved HDPE pipes for piping application for all Irrigation and drinking water projects with Horizontal Direct Drilling technology, without disturbing urban life. HDPE pipes are installed in a 500km stretch in India for a drinking water project.

The application of Sudarshan HDPE pipes is best preferred for:

- Lifting and extraction of water from a bore well with submersible pipes.

- Transportation of water from rivers, canals, ponds, and lakes

- Lift the irrigation water supply from a different source to the farmland

- Drinking water projects for village industries

- Ducting of electrical and telecom cables

- Municipal Drainage System

- Drinking water projects to village/Layout/Smart cities with Sudarshan HDPE Pipes:

Drinking water is transported from Sudarshan HDPE Pipe PE 100 PN8/PN 10 material and connected to each house with MDPE pipe Dia 20mm/25mm. Sudarshan HDPE pipes are jointed through Butt welding which makes them leak-proof. HDPE pipes are ideal/ easy installation/low-cost and maintenance, and no loss of water. - Irrigation-water transportation from River/Canal/Lakes to farmland with Sudarshan HDPE Pipe Under Irrigation – Water transportation from Canal/River:

HDPE pipes (PE 100) with diameters ranging from 110 mm to 315 mm and pressure ratings from PN 10 to PN 20 are ideal for transporting water from canals and withstanding the pressure of high-capacity pumps. Water distribution to villages and farms is typically done using smaller HDPE pipes with diameters from 63 mm to 140 mm (PE 100, PN 8/PN 10). Farms are then connected through drip pipes and sprinkler irrigation systems. - Lifting and extraction of water from the bore well with a submersible pump, with Sudarshan HDPE pipe:

Sudarshan HDPE pipe PE 80/ PE 100 – 32mm to 63mm are most suitable to lift water from a Borewell from 100ft to 1500ft deep Borewell. Different pressure ratings PN 6/ PN 8/ PN 10/ PN 12.5/ PN 16/ PN 20/ PN 25- Pipes are used according to the depth of the Borewell. Sudarshan HDPE Pipe replaced all other conventional pipes, i.e., G.I. / Column Pipe, due to easy installation, low cost & no maintenance.

|

SDR

|

SDR 41

|

SDR 33

|

SDR 26

|

SDR 21

|

SDR 17

|

SDR 13.6

|

SDR 11

|

SDR 9

|

SDR 7.4

|

SDR 6

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

PE63

PE80 PE100 |

PN 2

Pn 2.5 PN 3 |

PN 2.5

Pn 3.2 PN 4 |

PN 3.2

PN 4 PN 5 |

PN 4

PN 5 PN 6 |

PN 5

PN 6 PN 8 |

PN 6

PN 8 PN 10 |

PN 8

PN 10 PN 12.5 |

-

PN 12.5 PN 16 |

-

PN 16 PN 20 |

-

PN 20 - |

||||||||||

|

Nominal OD

DBn in mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

eMin

mm |

eMax

mm |

|

16

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.8

|

2.1

|

2.2

|

2.5

|

2.7

|

3.1

|

|

20

|

|

|

|

|

|

|

|

|

|

|

|

|

1.9

|

2.2

|

2.3

|

2.6

|

2.7

|

3.1

|

3.4

|

3.8

|

|

25

|

|

|

|

|

|

|

|

|

|

|

1.9

|

2.2

|

2.3

|

2.6

|

2.8

|

3.2

|

3.4

|

3.8

|

4.2

|

4.7

|

|

32

|

|

|

|

|

|

|

|

|

1.9

|

2.2

|

2.4

|

2.7

|

2.9

|

3.3

|

3.6

|

4.1

|

4.4

|

4.9

|

5.4

|

6

|

|

40

|

|

|

|

|

|

|

1.9

|

2.2

|

2.4

|

2.7

|

3

|

3.4

|

3.7

|

4.2

|

4.5

|

5.1

|

5.4

|

6

|

6.7

|

7.5

|

|

50

|

|

|

|

|

2

|

2.3

|

2.4

|

2.7

|

3

|

3.4

|

3.7

|

4.2

|

4.6

|

5.2

|

5.6

|

6.3

|

6.8

|

7.6

|

8.4

|

9.3

|

|

63

|

|

|

|

|

2.5

|

2.9

|

3

|

3.4

|

3.7

|

4.2

|

4.7

|

5.3

|

5.8

|

6.5

|

7

|

7.8

|

8.6

|

9.6

|

10.5

|

11.7

|

|

75

|

1.9

|

2.2

|

2.3

|

2.6

|

2.9

|

3.3

|

3.6

|

4.1

|

4.5

|

4.5

|

5.6

|

6.3

|

6.9

|

7.7

|

8.4

|

9.3

|

10.2

|

11.3

|

12.5

|

13.9

|

|

90

|

2.2

|

2.5

|

2.8

|

3.2

|

3.5

|

4

|

4.3

|

4.8

|

5.3

|

5.9

|

6.7

|

7.5

|

8.2

|

9.1

|

10

|

11.1

|

12.2

|

13.5

|

15

|

16.6

|

|

110

|

2.7

|

3.1

|

3.4

|

3.8

|

4.3

|

4.8

|

5.3

|

6.0

|

6.5

|

7.3

|

8.1

|

9

|

10

|

11.1

|

12.3

|

13.6

|

14.9

|

16.5

|

18.4

|

20.3

|

|

125

|

3.1

|

3.5

|

3.8

|

4.3

|

4.8

|

5.4

|

6

|

6.7

|

7.4

|

8.2

|

9.2

|

10.2

|

11.4

|

12.7

|

13.9

|

15.4

|

16.9

|

18.7

|

20.9

|

23.1

|

|

140

|

3.5

|

4

|

4.3

|

4.8

|

5.4

|

6

|

6.7

|

7.5

|

8.3

|

9.2

|

10.3

|

11.4

|

12.8

|

14.2

|

15.6

|

17.3

|

19

|

21

|

23.4

|

25.8

|

|

160

|

3.9

|

4.4

|

4.9

|

5.5

|

6.2

|

6.9

|

7.7

|

8.6

|

9.5

|

10.6

|

11.8

|

13.1

|

14.6

|

16.2

|

17.8

|

19.7

|

21.7

|

24

|

26.7

|

29.5

|

|

180

|

4.4

|

4.9

|

5.5

|

6.2

|

7

|

7.8

|

8.6

|

9.6

|

10.6

|

11.8

|

13.3

|

14.7

|

16.4

|

18.1

|

20

|

22.1

|

24.4

|

26.9

|

30

|

33.1

|

|

200

|

4.9

|

5.5

|

6.1

|

6.8

|

7.7

|

8.6

|

9.6

|

10.7

|

11.8

|

13.1

|

14.7

|

16.3

|

18.2

|

20.1

|

22.3

|

24.6

|

27.1

|

29.9

|

33.4

|

36.8

|

|

225

|

5.5

|

6.2

|

6.9

|

7.7

|

8.7

|

9.7

|

10.8

|

12

|

13.3

|

14.7

|

16.6

|

18.4

|

20.5

|

22.7

|

25

|

27.6

|

30.5

|

33.7

|

37.5

|

41.4

|

|

250

|

6.1

|

6.8

|

7.6

|

8.5

|

9.7

|

10.8

|

12

|

13.3

|

14.7

|

16.3

|

18.4

|

20.3

|

22.8

|

25.2

|

27.8

|

30.7

|

33.8

|

37.3

|

41.7

|

46

|

|

280

|

6.9

|

7.7

|

8.5

|

9.5

|

10.8

|

12

|

13.4

|

14.8

|

16.5

|

18.3

|

20.6

|

22.8

|

25.5

|

28.2

|

31.2

|

34.4

|

37.9

|

41.8

|

46.7

|

51.5

|

|

315

|

7.7

|

8.6

|

9.6

|

10.7

|

12.2

|

13.5

|

15

|

16.6

|

18.6

|

20.6

|

23.2

|

35.6

|

28.7

|

31.7

|

35

|

38.6

|

42.6

|

47

|

52.5

|

57.9

|

|

355

|

8.7

|

9.7

|

10.8

|

12

|

13.7

|

15.2

|

16.9

|

18.7

|

20.9

|

23.1

|

26.1

|

28.8

|

32.3

|

35.6

|

39.5

|

43.6

|

48

|

52.9

|

59.2

|

65.2

|

|

400

|

9.8

|

10.9

|

12.2

|

13.5

|

15.4

|

17

|

19.1

|

21.1

|

23.6

|

26.1

|

29.5

|

32.6

|

36.4

|

40.1

|

44.5

|

49.1

|

54.1

|

59.6

|

66.7

|

73.5

|

|

1.1

|

Visual Appearance and Dimensions

|

Visual

|

As per clause no 9.2 of IS: 4984-2016

|

As per Clause 7.1 & 7.4, Table-9 of IS 4894-2016

|

|---|---|---|---|---|

|

1.2

|

Longitudinal Reversion Test

|

Measurement

|

As per Clause 8.2 & Annex. F of IS 4894-2016

|

Shall not be more than 3%; No effect on the surface

|

|

1.3

|

Carbon Black Content

|

Measurement

|

As per Clause 8.3 of IS:4984 - 2016, IS:2530

|

Shall be 2.5% ± 0.5%

|

|

1.4

|

Carbon Black Dispersion

|

Measurement

|

As per Clause 8.3 of IS:4984 - 2016

|

Shall be satisfactory

|

|

1.5

|

Melt Flow rate at 190 °C / 5 Kg

|

Measurement

|

As per Clause 8.4 of IS:4984 - 2016 and IS:2530

|

Maximum deviation of 30% of the Nominated value

|

|

1.6

|

Density at 27% (Base Density)

|

Measurement

|

As per Clause 8.7 of1S 4984 - 2016 / IS 7328

|

940 to 960 Kg/m

|

|

1.7

|

Oxidation Induction Time (OIT)

|

Measurement

|

As per clause 8.5 & Annex-B of IS:4984-2016

|

> 20 minutes

|

|

1.8

|

Elongation at Break

|

Measurement

|

Clause no 8.9 of IS: 4984 - 2016 (Annex-H) & Table 6

|

≥ 350%

|

|

1.9

|

Internal Pressure Creep Rupture Test (hydrostatic resistance test) at 80°C for 48hrs

|

Measurement

|

As per IS: 4984: 2016 Clause No: 8.1.1, 9.2, Table 5 & Annex-E of IS:4984-2016

|

No signs of localized swelling, leakage or weeping and shall not burst during the prescribed test period

|

|

2

|

Internal Pressure Creep Rupture Test (hydrostatic resistance test) for joints at 80°C for 48hrs

|

Measurement

|

As per IS: 4984: 2016 Clause No: 8.1.2, 9.2, Table 5 & Annex-E of IS:4984-2016

|

No signs of localized swelling, leakage or weeping and shall not burst during the prescribed test period

|

|

2.1

|

Tensile strength for Butt Fusion

|

Measurement

|

Clause no 8.8 of IS:4984 - 2016 (Annex-G) & Amendment No.2 of IS:14846 - 2016

|

Shall not show brittle failure

|

|

2.2

|

Overall Migration Test

|

Measurement

|

Clause no 8.6 of IS:4984 - 2016, IS:9845 & IS:10146

|

Max. 10 mg/dm2

|

|

2.3

|

Internal Pressure Creep Rupture Test (hydrostatic resistance test) at 27°C for 100hrs (Type Test)

|

Measurement

|

As per IS: 4984: 2016 Clause No: 8.1.1, 9.1, Table 5 & Annex-E of IS:4984-2016

|

No signs of localized swelling, leakage or weeping and shall not burst during the prescribed test period

|

|

2.4

|

Internal Pressure Creep Rupture Test (hydrostatic resistance test) at 80°C for 165hrs (Type Test)

|

Measurement

|

As per IS: 4984: 2016 Clause No: 8.1.1, 9.1, Table 5 & Annex-E of IS:4984-2016

|

No signs of localized swelling, leakage or weeping and shall not burst during the prescribed test period

|

|

2.5

|

Internal Pressure Creep Rupture Test (hydrostatic resistance test) at 80°C for 1000hrs (Type Test)

|

Measurement

|

As per IS: 4984: 2016 Clause No: 8.1.1, 9.1, Table 5 & Annex-E of IS:4984-2016

|

No signs of localized swelling, leakage or weeping and shall not burst during the prescribed test period

|

|

2.6

|

Slow Crack Growth Rate at 80°C for 500hrs (Type Test)

|

Measurement

|

As per IS: 4984: 2016 Clause No: 8.10, 9.1 & Annex-J of IS:4984-2016

|

No signs of localized swelling, leakage or weeping and shall not burst during the prescribed test period

|