Pipes for Metro Projects in India

Driving Metro Infrastructure with Reliable Piping Solutions

In today’s rapidly developing urban landscape, especially in metro projects,

underground infrastructure plays a vital role in maintaining the smooth flow

of electricity, water, data, and waste management. To keep city spaces

organized and free for transportation and public movement, essential utilities

like power cables, fiber optics, drainage lines, and water supply systems are all

laid below the surface.

To protect these lifelines, we use specialized plastic piping systems that offer

long-term durability and safety. Whether it’s HDPE for water transport, DWC

for drainage and cable ducting, SWC for structural precast, or PLB ducts for

electrical wiring, each pipe is selected to ensure efficient and secure

operations beneath the city—supporting the heart of metro infrastructure

without disrupting its surface.

Different Types of Pipes Used in Metro Projects

| Type of Pipes | Application | Used For |

|---|---|---|

| Single Wall Corrugated | Bridges, flyovers, viaducts, tunnels, and underpasses | Used for post-tensioned concrete structures such as bridges, flyovers, viaducts, tunnels, and underpasses |

| Double Wall Corrugated (Drainage & Sewerage) | Drainage System (75mm–1000mm) | Managing stormwater and sewage due to their high load-bearing capacity and corrosion resistance. |

| Road & Highway Construction | Providing subsurface drainage solutions that prevent waterlogging and maintain pavement integrity. | |

| Double Wall Corrugated (Cable) | Cable Protection | Safeguarding electrical and telecommunication cables from mechanical damage and environmental factors. |

| HDPE | Water Supply and Distribution | HDPE pipes ensure a safe, leak-free water supply with their corrosion-resistant and durable design. |

| PLB DUCT | Signal and Communication Systems | Safely housing optical fibre cables is vital for train control and real-time communication. |

| Electrical Cable Routing | Providing a protective conduit for electrical cables, ensuring uninterrupted power supply. | |

| Data Transmission | Facilitating easy installation of data cables with their smooth, lubricated interior surface. | |

| Surveillance and Security Systems | Routing cables for CCTV and security equipment, ensuring their protection and optimal functioning. |

| Size Nominal ID (MM) | Size Nominal OD (MM) | Wall thickness |

|---|---|---|

| 75 MM | 90 MM | 2.30 MM to 2.80 MM |

| 84 MM | 97 MM | 2.50 MM to 3.50 MM |

| 107 MM | 125 MM | 2.50 MM to 3.50 MM |

| 128 MM | 148MM | 2.50 MM to 3.50 MM |

|

AS PER

|

||||

|---|---|---|---|---|

|

|

|

WALL THICKNESS

|

|

|

|

SL No

|

Size

|

AWT

|

TR + -

|

WT/Mtr

|

|

1

|

90/77

|

2

|

0.3

|

0.560

|

|

2

|

98/85

|

2

|

0.3

|

0.670

|

|

3

|

122/107

|

2.3

|

0.3

|

0.850

|

SWC Pipes for Metro Projects

SWC pipes for metro projects are mainly used in post-tensioned

concrete structures such as bridges, flyovers, viaducts,

tunnels, and underpasses. They help in creating ducts

through which iron rods or cables are passed before

pouring concrete, making the structure stronger and

more stable. These pipes are also used during the

casting of pillars and slabs to ensure proper

placement of reinforcement.

Sudarshan SWC Pipes are specifically designed to meet rigorous demands. Manufactured using premium-grade High-Density Polyethylene (HDPE), these pipes offer excellent flexibility, corrosion resistance, and a long service life, even under harsh underground conditions.

Produced using state-of-the-art extrusion technology

and adhering to industry standards like IS 14930,

Sudarshan SWC pipes ensure consistency, reliability,

and top-tier performance. Available in various sizes

and load-bearing capacities, these pipes are tailormade for metro projects.

| Size Nominal ID (MM) | Size Nominal OD (MM) | Wall thickness |

|---|---|---|

| 75 MM | 90 MM | 2.30 MM to 2.80 MM |

| 84 MM | 97 MM | 2.50 MM to 3.50 MM |

| 107 MM | 125 MM | 2.50 MM to 3.50 MM |

| 128 MM | 148MM | 2.50 MM to 3.50 MM |

|

AS PER

|

||||

|---|---|---|---|---|

|

|

|

WALL THICKNESS

|

|

|

|

SL No

|

Size

|

AWT

|

TR + -

|

WT/Mtr

|

|

1

|

90/77

|

2

|

0.3

|

0.560

|

|

2

|

98/85

|

2

|

0.3

|

0.670

|

|

3

|

122/107

|

2.3

|

0.3

|

0.850

|

Features and Benefits

- Superior Corrosion Protection

- Provide Solid Bonding with Concrete

- High Stiffness, Flexibility and Light Weight

- Consistent Quality

- Available In Various Length Options

- Speed Installation Due to Fewer Joints

- Produced With High Quality Raw Material

- In-House Wel-Equipped Testing Facility

- Latest Technology Machinery

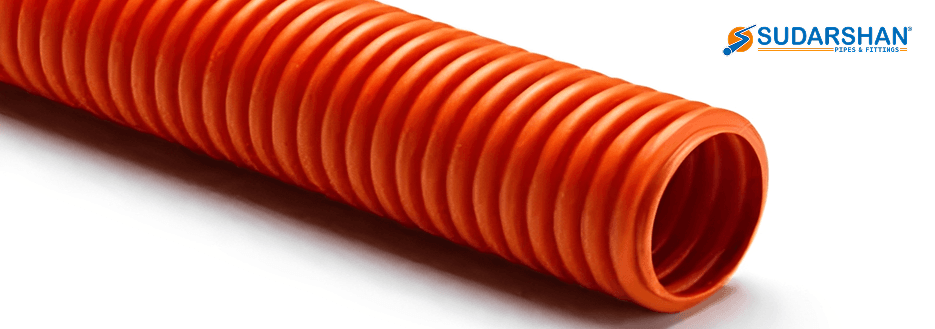

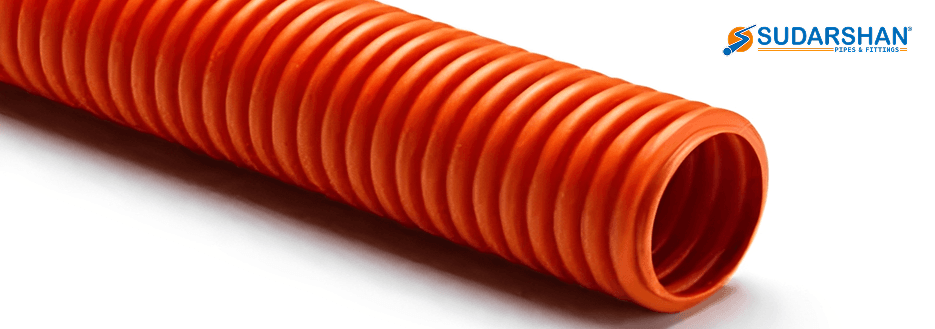

DWC Pipes (Cable) for Metro Projects

DWC pipes are used to protect electrical and

communication cables in Metro Rail Network. Their

strong double-wall design protects cables from

damage from soil pressure, moisture, or construction

activities. These pipes are flexible, lightweight, and

easy to install underground, making them ideal for

cable management in complex metro networks.

Made from premium High-Density Polyethylene

(HDPE), Sudarshan DWC pipes provide strong

resistance to stress, cracks, and harsh environments.

Manufactured using advanced machinery, Sudarshan

DWC Pipes maintain high quality and meet IS 16205 –

Part 24 standards.

From power to signalling and communication lines,

these pipes ensure long-lasting protection and easy

handling—making them a trusted choice for

engineers in urban infrastructure

Technical Specifications

|

CONDUIT SYSTEMS FOR CABLE MANAGEMENT IS:16205 (Part 24)

|

||||

|---|---|---|---|---|

|

SL No

|

Nominal Size

|

Nominal O.D

|

Tolerances

|

Min I.D

|

|

1

|

25

|

25

|

+ 0.5

|

18

|

|

2

|

32

|

32

|

+ 0.6

|

24

|

|

3

|

40

|

40

|

+ 0.8

|

30

|

|

4

|

50

|

50

|

+ 1.0

|

37

|

|

5

|

63

|

63

|

+ 1.2

|

47

|

|

6

|

75

|

75

|

+ 1.4

|

56

|

|

7

|

90

|

90

|

+ 1.7

|

67

|

|

8

|

110

|

110

|

+ 2.0

|

82

|

|

9

|

120

|

120

|

+ 2.2

|

90

|

|

10

|

125

|

125

|

+ 2.3

|

94

|

|

11

|

140

|

140

|

+ 2.6

|

106

|

|

12

|

160

|

160

|

+ 2.9

|

120

|

|

13

|

180

|

180

|

+ 3.3

|

135

|

|

14

|

200

|

200

|

+ 3.6

|

150

|

|

15

|

225

|

225

|

+ 4.1

|

170

|

|

16

|

250

|

250

|

+ 4.5

|

188

|

|

17

|

315

|

315

|

+ 5.7

|

237

|

Features and Benefits

- Excellent Stiffness

- Excellent Chemical, Corrosion and Abrasion Resistance

- Great Flexibility

- Easy And Quick Installation

- Cost Effective

- Eco-Friendly

- Long-Life

Technical Specifications

|

CONDUIT SYSTEMS FOR CABLE MANAGEMENT IS:16205 (Part 24)

|

||||

|---|---|---|---|---|

|

SL No

|

Nominal Size

|

Nominal O.D

|

Tolerances

|

Min I.D

|

|

1

|

25

|

25

|

+ 0.5

|

18

|

|

2

|

32

|

32

|

+ 0.6

|

24

|

|

3

|

40

|

40

|

+ 0.8

|

30

|

|

4

|

50

|

50

|

+ 1.0

|

37

|

|

5

|

63

|

63

|

+ 1.2

|

47

|

|

6

|

75

|

75

|

+ 1.4

|

56

|

|

7

|

90

|

90

|

+ 1.7

|

67

|

|

8

|

110

|

110

|

+ 2.0

|

82

|

|

9

|

120

|

120

|

+ 2.2

|

90

|

|

10

|

125

|

125

|

+ 2.3

|

94

|

|

11

|

140

|

140

|

+ 2.6

|

106

|

|

12

|

160

|

160

|

+ 2.9

|

120

|

|

13

|

180

|

180

|

+ 3.3

|

135

|

|

14

|

200

|

200

|

+ 3.6

|

150

|

|

15

|

225

|

225

|

+ 4.1

|

170

|

|

16

|

250

|

250

|

+ 4.5

|

188

|

|

17

|

315

|

315

|

+ 5.7

|

237

|

DWC Pipes (Drainage and Sewerage) for Metro Projects

When it rains or wastewater needs to be drained from metro

stations or tunnels, strong and long-lasting pipes are needed.

That’s when DWC pipes are used for underground drainage

and sewerage systems. Their tough outer layer provides

strength, while the smooth inner layer ensures easy flow of

water and waste. These pipes are perfect for handling heavy

loads and are resistant to chemicals, making them ideal for

metro drainage systems.

Sudarshan DWC Pipes are lightweight, easy to transport, and

simple to install, making them ideal for fast-paced metro

projects. Their structural integrity and leak-proof joining system

ensure long service life even under harsh conditions.

Produced using advanced machinery and strict quality

controls, these pipes conform to IS 16098 – Part 2 standards and

are available in stiffness classes like SN4 and SN8, meeting the

demanding needs of large-scale urban drainage networks.

| MATERIAL | HDPE |

|---|---|

| Thickness | 1 Inch To 4 Inch Or 20mm To 110mm |

| Length | 19m to 25m |

| Application | Plumbing, Utilities Water, Drinking Water |

| Diameter | >4 inch |

| Connection End Type | Flange, Welded |

| Material Grade | PE-80 & PE-100, PE-63 |

| Durability | Long Life |

Technical Specifications

|

Wall Thickness Chart As per IS 16098 (Part-2): 2013

|

||||

|---|---|---|---|---|

|

Nominal OD/ID

|

OD

|

ID

|

|

|

|

OD

|

ID

|

Min Wall Thickness

|

Min Wall Thickness

|

Socket Length

|

|

75

|

71

|

1

|

0.85

|

25

|

|

100

|

95

|

1

|

1

|

32

|

|

125

|

120

|

1.2

|

1

|

38

|

|

135

|

130

|

1.2

|

1

|

39

|

|

150

|

145

|

1.3

|

1

|

43

|

|

170

|

165

|

1.4

|

1

|

48

|

|

200

|

195

|

1.5

|

1.1

|

54

|

|

225

|

220

|

1.7

|

1.4

|

55

|

|

250

|

245

|

1.8

|

1.5

|

59

|

|

300

|

294

|

2

|

1.7

|

64

|

|

400

|

392

|

2.5

|

2.3

|

74

|

|

500

|

490

|

3

|

3

|

85

|

|

600

|

588

|

3.5

|

3.5

|

96

|

Features and Benefits

- Easy to handle, transport, and store

- Easy to install

- Superior performance to RCC Pipes

- Long life

- Available in a long length of 6 meters so minimum joints, ensuring less

chances of leakage - Corrosion & abrasion resistant

- Anti-rodent material

| MATERIAL | HDPE |

|---|---|

| Thickness | 1 Inch To 4 Inch Or 20mm To 110mm |

| Length | 19m to 25m |

| Application | Plumbing, Utilities Water, Drinking Water |

| Diameter | >4 inch |

| Connection End Type | Flange, Welded |

| Material Grade | PE-80 & PE-100, PE-63 |

| Durability | Long Life |

| ASPECT | DETAILS |

|---|---|

| Current Product Range | Pipes from 20 mm to 400 mm diameter in PE80/PE100 |

| Current Installed Capacity | 48,000 MTP with 16 extruders (highest in South India) |

| Future Installed Capacity | 60,000 MTP (post-expansion) |

| Material Used | Pre-compounded black material ‘Borrouge’ |

| Facilities | Highly technical manpower, in-house labs, testing and research facilities |

| Quality Control | Online and offline stringent quality control system |

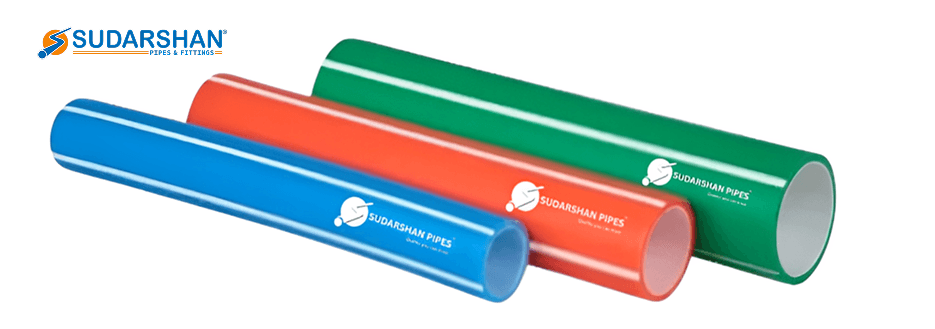

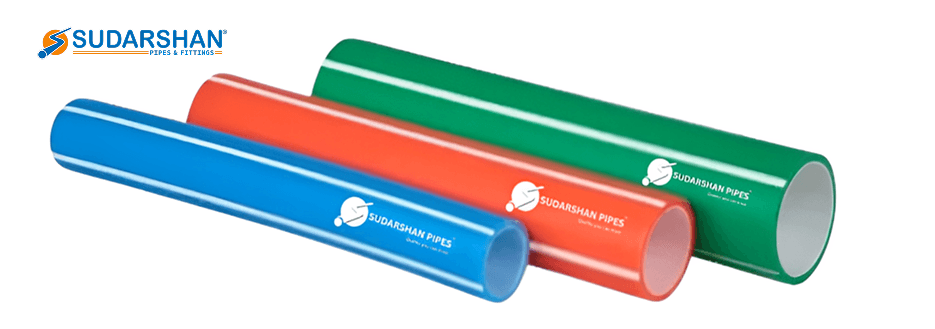

HDPE Pipes for Metro Projects

Supplying clean water to metro stations and nearby areas is essential for operations and public use. HDPE pipes for metro projects are used to carry drinking water and for water distribution systems. They are strong, leak-proof, and resistant to rust or chemicals. Their flexibility allows easy installation even in tricky or tight spaces, making them perfect for water supply in metro construction.

Introducing Sudarshan HDPE Pipes –

engineered to meet the rigorous demands of

urban infrastructure. Their smooth inner surface

ensures minimal friction, facilitating efficient

water flow and reducing maintenance needs.

Manufactured as per IS 4984:2016 (Drinking

Water) and IS 14333:2018 (Drainage and

Sewerage) standards, adhering to the highest

quality benchmarks. Producing from PE63,

PE80, and PE100 grades, ensuring high tensile

strength and long-term performance.

| ASPECT | DETAILS |

|---|---|

| Current Product Range | Pipes from 20 mm to 400 mm diameter in PE80/PE100 |

| Current Installed Capacity | 48,000 MTP with 16 extruders (highest in South India) |

| Future Installed Capacity | 60,000 MTP (post-expansion) |

| Material Used | Pre-compounded black material ‘Borrouge’ |

| Facilities | Highly technical manpower, in-house labs, testing and research facilities |

| Quality Control | Online and offline stringent quality control system |

| Suitable For | Telecommunication, metro systems, national highways, Railways, Real Estate, Telecom, Solar, Residential and Industrial Layout |

| Market Position | Trusted as the top quality product. |

Features and Benefits

- Easy to handle

- Virgin Raw Material

- Strong and Durable

- Chemical Resistant

- Leak-Proof Joint

- Lightweight

Standards and Specifications

IS:4984 (2016)

For drinking water pipelines

IS:14333 (1996)

For drainage water

PLB Duct for Metro Projects

Behind every metro project is a complex web of fibre optic

cables connecting communication and signalling systems.

PLB ducts are used to house and protect these fibre optic

cables. Their inner lubricated layer helps in easy and longdistance cable blowing. These ducts are essential for

maintaining smooth communication systems in metro

railways, stations, and control rooms.

Manufactured as per RITES and TSEC 2019 standards,

Sudarshan PLB Duct Pipes are made from high-grade

HDPE with a solid silicone lubricated inner layer, ensuring

low friction for smooth cable installation. Their flexibility

allows easy routing through bends, making them ideal for

complex urban infrastructure.

Common sizes include 32/26mm, 40/33mm, and 50/42mm.

Widely used in fiber optic and telecom cable laying.

| FEATURE | DESCRIPTION |

|---|---|

| Manufacturing Standards | TEC 2019 standards |

| Certifications | TSEC certification with RITES inspection |

| Purpose | Safeguard fibre optic cables in crucial infrastructure projects |

| Inner Layer | Well-lubricated, reduces friction, assures seamless installation, decreases risk of cable damage |

| Applications | Underground laying of optical fibre cables |

| Extensive Use | Indian Railways (telecom and signaling), 4G/5G network deployments, BHARATNET project, and more |

| Suitable For | Telecommunication, metro systems, national highways, Railways, Real Estate, Telecom, Solar, Residential and Industrial Layout |

| Advantages | Superior protection and durability |

Features and Benefits

- Permanent Lubrication

- High Flexibility

- UV Resistant

- Lightweight & Easy to Handle

- Moisture & Chemical Resistance

- Thermal Stability

| FEATURE | DESCRIPTION |

|---|---|

| Manufacturing Standards | TEC 2019 standards |

| Certifications | TSEC certification with RITES inspection |

| Purpose | Safeguard fibre optic cables in crucial infrastructure projects |

| Inner Layer | Well-lubricated, reduces friction, assures seamless installation, decreases risk of cable damage |

| Applications | Underground laying of optical fibre cables |

| Extensive Use | Indian Railways (telecom and signaling), 4G/5G network deployments, BHARATNET project, and more |

| Suitable For | Telecommunication, metro systems, national highways, Railways, Real Estate, Telecom, Solar, Residential and Industrial Layout |

| Advantages | Superior protection and durability |

Download the brochure for more information

SWC Pipes brochure

DWC Pipes (Cable) brochure

DWC Pipes (Drainage and Sewerage) brochure

HDPE Pipes brochure

Buy Pipes for Metro Projects in India from Sudarshan Pipes

So, elevate your metro project with us, the trusted name in the world of piping solutions. We have 30+ years of experience, 6,000+ dealers, and 3,500+ contractors that will help you take the project to the next level. With a satisfied customer base, we have an extensive network of over 400 Distributors, 6000 Dealers and 3500 Contractors across India and globally. So, what are you waiting for? Get in touch with us today and get your piping sorted!